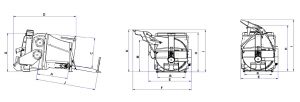

Caring about developing our ranges while the agricultural world is changing, EUROMARK conceived a small volume straw blower, with as much performance as big machines : the BOOSTER 2D2. With its small size and its long-thought conception, BOOSTER 2D2 small volume straw blower brings you maximal efficiency with minimum clutter.

EUROMARK furnished this model with two S.D.E. mechanical separators equipped with 40 sections each; this Strung Bale Distribution ensures you a quality mulch and gives the seperators high performance for all fodders. With a 2.8m³ useful capacity, its tank has been conceived for all bales (round : ± 2m of diameter and square : ± 2m50 of length). With great adaptability, double-seperators small volume BOOSTER 2D2 is available in various versions in order to fulfill all your needs and fit in every building.

EUROMARK double-seperators small volume BOOSTER 2D2 is thus available :

- In lateral chute version ,

- Or in POLYFLOW central chute version.

POWERDRIVE technology

To spread difficult products, BOOSTER 2D2 can be equipped with a carrying system by hydraulicly disengageable belt. POWERDRIVE system is an EUROMARK patented innovation (optional feature).

A broad choice of options expands this machine’s equipment, in order to ensure you an efficient and performing work instrument, adapted to your daily needs.