Versatile, EUROMARK TXV6/9/11/13XL & TXW16/19/22XL mixer and straw blowers are real assets of a balanced and quality feed.

Thanks to their precise weighing system, they enable you to prepare mixed rations, adapted to your cattle’s needs. Our mixer and straw blowers range allows you to adjust rations by calculing the quantity of each component. Intuitive and highly precise, this system linked to the four load cells on the chassis enables you to weigh every ration ingredient and to have an exact management of the final mix.

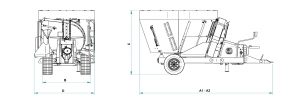

The rounded-shape caisson, the position and pattern of stepped screw/s have been especially studied to ensure the products’ free flow through the machine : guarantee of matters’ respect and of mix homogeneity. Single or twin screws, their low height (from 2m46) enables distribution in lowest buildings.

EUROMARK Vertical screws mixer and straw blowers range is available:

- In single screw version from 6 to 13m³ – 6m³, 9m³, 11m³ and 13m³ -, making mixers usable to all breeding, even those with little ration needs.

- And in twin screws version from 16 to 22m³ – 16m³, 19m³, 22m³, allowing big rations mixing.

In standard version, EUROMARK TXV6/9/11/13XL & TXW16/19/22XL vertical screw mixer and straw blowers are equipped with lateral chute.

Adapted unloading

With a great adaptability, EUROMARK mixer and straw blowers TXV6/9/11/13XL & TXW16/19/22XL are available in various versions in order to fulfill all uses and to fit space configuration. Our single and twin vertical screws mixer and straw blowers are delivred with different choices of unloading :

- Lateral unloading: Right-front or left-back unloading door,

- Transverse unloading: Front or back, right or left unloading belt.

A wide choice of options also enriches the machine’s equipment in order to ensure an efficient, powerful work tool adapted to your daily needs.